Record keeping is an important component for compliance to the Produce Safety Rule (PSR), FSMA and in the various Good Agricultural Practices (GAP) Certificates. In this section we will provide record templates for both PSR and GAP and point out some differences. Note that the records have a place for the employee to sign or initial, and at the bottom, a place for the supervisor's signature at time of review. Also make sure your farm name and location are on each document.

What Records Do I Need To Keep?

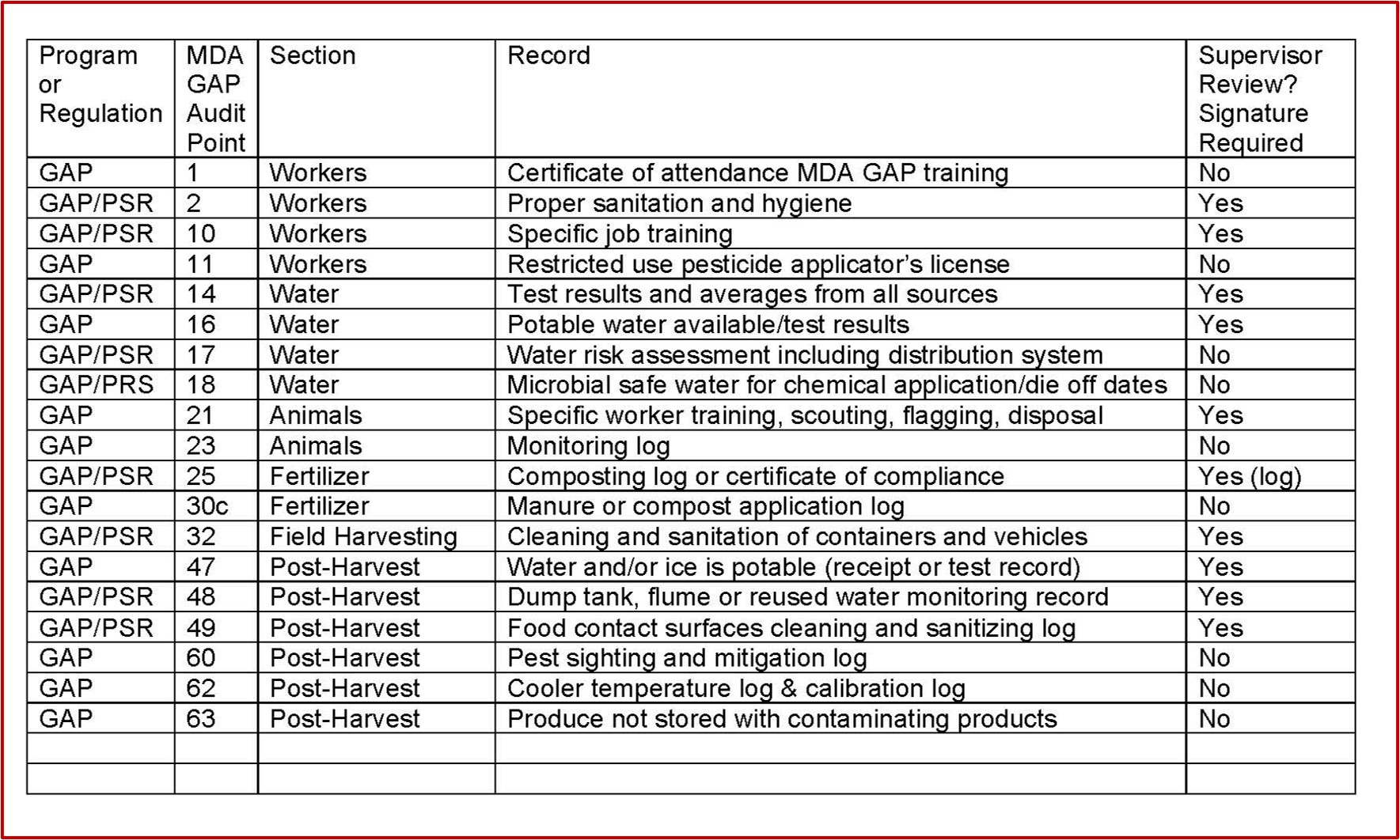

Do you need to be Produce Safety Rule compliant? Are you working on MDA GAP certification? Use this table to simplify your record keeping needs.

Worker Training

For PSR, workers must be trained in health and hygiene AND for specific tasks. Here is one template that can be used for both GAP and PSR. Notice that the farmer can write in the topic of the training, whether it is Health & Hygiene, COVID-19 cleaning and sanitation, or loading trucks. For the PSR, the record must be signed by each employee and the supervisor.

Testing, Monitoring, and Treating Irrigation Water and Inspecting Water Systems for Agricultural Water and Post Harvest Water

Water standards may differ for PSR and GAP certification, but in both cases records must be kept. It should be noted that water quality standards for PSR have not been finalized; however, the savvy farmer will want to know how the farm's water quality can affect produce safety.

Water System Inspection is a requirement of both GAP and PSR. Most farmers are already walking their water system at the start of the season. They start at the source, look at wells, pressure tanks, pipes, and connections from source to field. Delivery of agricultural (irrigation) water can vary from drip tape to overhead boom, but before their first use those devices need to be inspected and repaired if needed. A map, sophisticated or a casual sketch, should accompany the inspection record.

Water tests can indicate higher than desired levels of generic E.coli. If so, a sanitizer may be injected into the system. This would be appropriate if the water is being applied through overhead irrigation and if applied close to the harvest date on covered produce. There are record templates for this activity and for calculating microbial die-off if that method is employed. If a farm's water is supplied by the municipal government, a sanitizer is already being delivered with the water. The government office can provide a certificate of water quality, and that should be kept with the other farm records.

If a farm's water is coming from a well (deeper than 40 feet), a water test for generic E.coli should be made at the start of the growing season. The test results should be kept with the farm records.

If a farm's water source is from a pond or stream, water tests (generic E. coli) need to be made at various times during the growing season, depending on the level of GAP certification. At this time the frequency of water testing for PSR has not been finalized. The farmer may want to take samples as for MD GAP compliance; one at the start of the growing season, one mid-point, and one at harvest. Those records need to be kept with the farm's food safety plan.

MDA GAP Water Risk Assessment Template

Water Distribution Inspection Record.GAP

Water System Inspection Record. PSR

Water Source Inspection Log.GAP

Agricultural Water Die Off Record. PSR

Postharvest water must meet potable water standards and be tested for turbidity and nitrates (MD GAP). Make sure water for the packing house is tested annually and those records kept. If a sanitizer is used in wash or dump tank water, that sanitizer's effectiveness must be monitored and those records kept.

Water Treatment Monitoring Log. GAP

Water Treatment Monitoring Log. PSR

Cleaning and Sanitizing

While thinking about the packing house, there are many tools, surfaces, and equipment that need routine cleaning and sanitizing. These events should be coordinated with the farm's production schedule and the specific crops grown. SOPs should be written, guiding the employee trusted with this important task, and an interval should be chosen and adhered to. Keep in mind that "Clean Breaks" are a good way to prevent movement of microbes from one crop to another. Routine inspection of food storage areas should be included while you are thinking about packing house cleaning and sanitation. There are record templates for recording those events.

Produce Storage Area Inspection and Cleaning Log

Packing House Surfaces Cleaning and Sanitizing Log

Food Contact Surface Cleaning and Sanitizing Log

Cleaning and Sanitizing Record

Cleaning and Sanitizing Record. PSR

Packing House Maintenance

There are additional tasks to be tracked in the packing house. Thermometers in the cold storage room and thermometers used for monitoring dunk tank temperatures need to be checked and calibrated. Very important monitoring and control of pests should be performed on a regular basis.

In the Field Activities and Monitoring

The use of composts, manures, and other soil amendments can be sources of human pathogens. When they are used and how they are handled on the farm should be recorded. Wildlife can be another source of contamination. Monitoring logs can provide information on changes in wildlife behavior and be an aid in formulation control strategies.

Manure and Untreated Soil Amendment Application Log

Wildlife and Domestic Animal Monitoring Log

Transportation

Transportation is often one of the last steps from field to consumer. Cleaning and sanitizing have their place here as well. If the produce requires refrigeration during transportation, that cooling system needs monitoring. Successful delivery will be based on a good load-in procedure. A checklist is below. Though it is written for a refrigerated truck, it can be modified to suit any truck.

Refrigerated Truck Loading Log

Mock Recall

The more advanced GAP certificates require that an annual "mock recall" be performed. A farm should be able to trace a crop one step forward and one step back. The Produce Safety Rule also suggests this as a good practice. The mock recall should be logged and be kept with the farm records