The University of Maryland Plant Science Department, Food Safety Group collaborates with the Maryland Department of Agriculture Food Quality Assurance Program, UMD Agriculture Law Education Initiative, and the University of Maryland Extension Food Safety to provide Maryland farmers and producers with support, education and assistance in fresh produce safety. (More about us here: https://youtu.be/KA8gbDyNOlo)

The past two decades have seen the implementation of both Good Agricultural Practices (GAP) and FSMA (Food Safety Modernization Act), Produce Safety Rule. Maryland farmers are aware that food safety ensures both healthy consumers and a healthy market.

The above collaborators provide training sessions in basic GAP and advanced GAP to assist growers in understanding food safety risks on their farm and developing/implementing a food safety plan to minimize those risks. The training can also assist growers in obtaining GAP certification frequently required by buyers. See below for more information on the GAP program and if certification is right for your farm.

The Produce Safety Rule is a federal law that requires compliance based on a farm's three-year- average annual produce sales. The training is taught by Produce Safety Alliance certified PSR trainers under the direction of a Lead Trainer. Participants receive certification of the training, which is one of the PSR requirements. See below for information.

Current information on both PSR and the GAP program can be found on the Plant Science Food Safety Group Newsletter. Sign up here: http://eepurl.com/gXlGQL

Subscribe to the Plant Science Food Safety Group Newsletter

In the News

the New Water Rule went into effect july 5, 2024

This new rule replaces the requirements for pre-harvest water (Subpart E) that were published in 2015. This rule is for all covered produce except sprouts. Read the full rule here: https://www.fda.gov/food/food-safety-modernization-act-fsma/fsma-final-rule-pre-harvest-agricultural-water#:~:text=The%20effective%20date%20is%20July%205%2C%202024

The pre-harvest water requirements published in 2015 included a general statement that agricultural water must be safe and adequate for its intended use and included a microbial water quality criterion. This resulted in frequent testing and maintaining a calculated geometric mean, particularly for surface water (ponds, streams, water barrels, above ground cisterns, and any water source that was exposed to the environment). Stakeholders felt this testing-based requirement was burdensome in its frequency and its cost.

This final rule is based on a system-wide risk assessment, including the water’s source, use practices, distribution system, crop characteristics, environmental conditions, nearby land use or other hazards. The now familiar water testing using generic E. coli as an indicator organism can be part of the risk assessment, but does not replace the new risk-based evaluation.

What remains the same is the requirement for annual reassessment, as well as reassessment with any significant change, such as addition of a new crop, change in water source, change in water use practices, flooding, or any change that would Impact produce safety.

There are a lot of supporting resources and fact sheets. They can be accessed from the FSMA Final Rule on Pre-Harvest Agricultural Water web site. To start, there is an introduction to the decision-making factors here

An in-depth discussion of the assessment factors is found here

Corrective and mitigation measures are discussed here

A flow sheet of Agricultural water assessments and risk-based outcomes can be found here

An interactive web-based analysis tool, Agricultural Water Assessment Builder, can be found here

If this seems too overwhelming, the Plant Science Food Safety Group members are trained to help you through the process.

The FDA is adapting an “educate before we regulate” policy, and there is a bit of time to adapt to the new rule. The effective date is July 5, 2024. Compliance dates:

- April 7, 2025: Covered farms for which, on a rolling basis, the average annual monetary value of produce the farm sold during the previous 3-year period is more than $500,000.

- April 6, 2026: Covered farms for which, on a rolling basis, the average annual monetary value of produce the farm sold during the previous 3-year period is more than $250,000 but not more than $500,000 (small businesses).

- April 5, 2027: Covered farms for which, on a rolling basis, the average annual monetary value of produce the farm sold during the previous 3-year period is more than $25,000 but no more than $250,000 (very small businesses).

*******************************************************************************************************

Clearing Up the Confusion between GAP Audits and PSR Inspections

Developing a food safety culture is an ongoing exercise that requires reminders, reinforcement and retraining. What about regulations? What about certificate (or audit) programs? Where do each of them begin, and who needs to either comply or elect to participate? That is where the confusion often comes in.

The confusion occurs because both GAP and PSR have many of the same practices and standards, and both encourage the development of a food safety culture on the farm.

The Produce Safety Rule (PSR) is a regulation under the Food Safety Modernization Act (FSMA) of 2011. This Act was the first revision of food safety laws since 1938. It came about due to the changes in the global food system and a better understanding of the consequences of foodborne illness. FSMA includes both animal (livestock and pet) and human foods. The PSR section of FSMA pertains to the safe production and handling of fresh produce for human consumption.

Although this is a federal regulation, it is enforced by the Maryland Department of Agriculture (MDA). Producers frequently wonder if the law applies to them. Necessary compliance to the regulation is based on how much food a farmer sells on a three-year rolling average and who buys the majority of the farm’s food. Go to https://psla.umd.edu/extension/produce-safety/does-produce-safety-rule-apply-my-farm to learn more.

Good Agricultural Practices (GAP) is a voluntary audit program that a farmer may request. Usually, a wholesale buyer requires a farm to have GAP certification before they will buy the farm’s produce. More recently, some direct-market farms are also earning GAP certification as proof to their consumers that food safety standards are practiced. Go to https://psla.umd.edu/extension/produce-safety/how-will-gap-certification-help-my-farm to learn more about GAP and the process to earning a certificate.

Harmonized Good Agricultural Practices (HGAP) is a voluntary certificate with more stringent practices and standards for food safety. Some of the larger grocery stores require this higher level of food safety audits before they will buy a farm’s produce. More information can be found here: https://www.ams.usda.gov/services/auditing/gap-ghp.

Food safety is often in the news, and as a producer, that causes concern to many. Farmers want to provide their customers with fresh, high quality produce whether they sell wholesale or in direct markets. Being involved in a food safety recall is damaging to a farm’s reputation and is a farmer’s worst nightmare. For that reason, there are science-based procedures and standards that will assist in the prevention of pathogen cross contamination in the growing, harvesting and handling of fresh produce.

There are several programs that producers may want to or need to observe. They all start with the overriding philosophy of food safety that is referred to as “developing a food safety culture” on the farm. What is a food safety culture? It is making the compliance to food safety standards second nature, such as washing hands after eating, using the toilet, working with animals or compost or any other chore where cross contamination may be an issue. It becomes reflexive muscle memory to not use a harvesting crate to hold cans of motor oil or personal possessions. It becomes reflexive to not put a dirty crate onto a food contact surface. There are many more examples of procedures that every employee and every owner need to commit to muscle memory in order to develop a food safety culture on the farm.

Still unsure or just want help? Contact Carol Allen (callen12@umd.edu, 240-994-5043)

If You Grow and Sell Dried Herbs, Be Food Safe

This informative PowerPoint was delivered at the recent urban farmer meeting. It contains guidelines for processing and selling dried herbs and teas.

Announcing a New Fact Sheet!

Managing Listeria in Drains

Listeria monocytogenes is a common, foodborne pathogen that thrives in cold to cool, moist areas. It can often be found in drains and spread to food contact surfaces during pack house or cooler cleaning. Tips on minimizing the spread of Listeria during both normal operations and during cleaning can be found in this factsheet.

How About GAP (Good Agricultural Practices) Certification?

It is never too late, or too early to become GAP certified. The Plant Science Food Safety Group is offering virtual classes in preparation to become certified in Maryland Good Agricultural Practices (MD GAP). GAP certification provides the assurance to customers that a farm is employing high standards in farming methods that reduce the likelihood of contaminating produce with food borne pathogens. This includes practices that address water quality, manure and compost use, worker health and hygiene and contamination from wild life, domestic animals and livestock.

This program is appropriate for the farm that has recently initiated direct marketing to consumers or the farm that is considering a wholesale contract. Also aspiring farmers would be wise to include GAPs when constructing their business models. Contact Carol Allen (callen12@umd.edu) for more information about the program.

We are part of the Walsh Research Lab. Check out what's new here

Who are we?

Carol Allen, MS

Carol grew up in the farm lands of upstate New York and currently resides adjacent to the agricultural reserve in Montgomery County, MD. She holds a Masters degree in Plant Science with a concentration in plant pathology, plant virus, and integrated pest management. Specifically, Carol is happiest when she is on the hunt for pests and diseases whether it be in the apple orchard, nursery, or greenhouse. Her background gives her the advantage of talking to farmers in their language and with the understanding of their particular issues. As an educator she has the skill to introduce new concepts and procedures in an easily understood manner. Carol is a PSA certified Produce Safety Rule trainer and is qualified to aid in On Farm Readiness Reviews. Contact Carol at callen12@umd.edu.

Angela Ferelli, Ph.D.

Angela Ferelli is an Agent Associate in Food Safety at the University of Maryland and a Produce Safety Alliance Lead trainer. She has a passion for effective science communication and translatable research that can aid growers in making on-farm risk assessments and management decisions. In addition to the Produce Safety Rule, she is also certified to assess risk for small food processors (PCQI) and in food defense (IA). Angela received her PhD from the University of Maryland, where she researched Salmonella enterica interactions with the tomato immune system and persistence in surface and reclaimed water. Contact Angela at angfer@umd.edu

The Produce Safety Specialists at the University of Maryland Plant Science Department provide assistance, education, and research to support farmers and producers reach their food safety goals. Together with our collaborators, we coordinate advanced and basic GAP trainings for DelMarVaPa farmers. We also provide assistance in food safety plan writing, GAP certification, irrigation water sampling, interpreting water sampling test results, and more!

Angela

What can we do for you?

Covid-19 Guidance For Maryland Farmers - En Español Tambien

MDA Guidance for PYO Operations During COVID-19 State of Emergency

Thank you to our collaborators for their input! This was a joint effort on the part of MDA and MDH with input from the Plant Science Food Safety Group and from the Agriculture Law Education Initiative.

The guidance is available in Spanish here.

La guia en Español esta disponible AQUI.

Maryland Pick-Your-Own Operations During

COVID-19 State of Emergency

MDA Issues Guidance for Farmer's Markets Operations During the COVID-19 State of Emergency: Frequently Asked Questions

Many farm markets will be opening soon and some are already seeing customers. With the loss of wholesale, other farmers are opening up to direct market sales. This is a time of new restrictions and new innovations. This document was written in collaboration with the Maryland Department of Health to insure both customers and farm personnel are protected. Read that here.

A Talk About COVID-19 for Your Spanish Speaking Workers

Keeping workers healthy has become more of an issue during this time of the COVID-19 pandemic than in any time in memory. A recorded talk in Spanish giving a basic introduction to what COVID-19 is all about, modes of transmission, prevention protocols and guidelines for day-to-day living can be found here. Also of interest is the part of Governor Hogan's March 30th speech that introduced the stay-at-home order and who it effects. You can listen to that here. Both of these recordings are in Spanish and are easily accessed on a cell phone

Una audio en Español dando una introduccion basica a todo lo referente al Covid-19: Modos de transmision, protocolos para prevenir contagios y guias para la vida dia a dia de pueden encontrar AQUI.

The script in English can be found here.

The script in Spanish can be found here.

El documents en Español de puede encontrar AQUI.

How Does COVID-19 Affect My Farm?

Watch this spot for updates on cleaning and sanitizing methods, worker training, and other topical issues.

Changes in cleaning and sanitizing and now disinfecting!

Strong cleaning and sanitizing programs not only maintain quality of your product but can also protect your product from food borne pathogens and pathogens of emerging public health concern.

Transmission of COVID-19 through food, food packages or even food handlers has not been identified as a risk factor for this illness. Food facilities are required to use EPA-registered “sanitizer” products in their normal cleaning and sanitizing practices. Nevertheless, research indicates that viruses like this type can stay viable on hard surfaces for a few hours to possibly longer.

Therefore, in addition to cleaning your food contact surfaces, identify other surfaces of interest to add into your cleaning and sanitizing program. These should include “high touch” surfaces such as doorknobs, small-wares, counter tops, light switches and surfaces consumers may touch. Surfaces to consider for disinfection*:

1.Doorknobs

2.Light switches

3.Tools

4.Counter tops

5.Break areas

6.Keyboards or other shared electronics / tools

7.Employee break area

8.Pack out containers that go to consumers

9.Anything else a consumer may interact with

*The FDA has authorized the following products and their dilution rates as effective disinfectants to be used in the case of COVID-19

What to do If an Employee or Contract Worker Tests Positive for COVID-19

Jennifer McEntire, Vice President of Food Safety and Technology at United Fresh, joined with several colleagues in the food industry to develop a guide for food chain employers on what to do when an employee or contract worker tests positive for COVID-19.

We anticipate that the ‘Food Industry Recommended Protocol When Employee/Customer Tests Positive for COVID-19’ will be posted soon on the FDA website; so please refer all employers, local, and state officials to this source,” says Tom Stenzel, President and CEO of United Fresh.

(quoted from Greenhouse Grower, an industry publication. Read the complete article here: https://www.greenhousegrower.com/production/what-to-do-if-a-food-industry-employee-tests-positive-for-covid-19/)

What Does the Stay-At-Home Order Mean To Me and My Workers?

Agriculture is considered an essential business. The Maryland Department of Agriculture guidance states, "Agriculture and food-related businesses remain essential, however individual companies are asked to make an honest assessment as to whether their operation is essential to public health and safety."

Workers are urged to minimize all unnecessary trips. Travel is allowed to obtain food, medicine, urgent medical care, assist family members, and obtain food and care for livestock and pets. Read full order here: https://governor.maryland.gov/wp-content/uploads/2020/03/Gatherings-FOURTH-AMENDED-3.30.20.pdf

The Maryland State Police will not be doing random checks, but as part of routine traffic activities, non essential travel would be an additional enforcement action. Read full statement here: https://news.maryland.gov/msp/2020/03/31/state-police-enforcement-of-governors-executive-orders-continues/

In the event a worker is detained, the following documents (templates, fill in pertinent information) have been created:

1. ESSENTIAL FOOD AND AGRICULTURAL INDEPENDENT CONTRACTOR WORK PERMIT

2. ESSENTIAL FOOD AND AGRICULTURAL EMPLOYEE WORK PERMIT

Documentation is not required, but the Maryland State Police order states, "While it is not necessary for drivers in Maryland to have documentation about the purpose of travel, having such documentation may help resolve questions."

How Will GAP Certification Help My Farm?

Maryland’s farmers and producers have a history of appreciating the relationship between their customers and their product. In the face of nationwide food borne illness outbreaks, it becomes vital to Maryland’s farmers to insure delivering safe, fresh produce to their markets.

In 1998 the first of several steps to standardize produce growing and handling was initiated when the FDA published the “Guide to Minimize Microbial Food Safety Hazards for Fresh Fruits and Vegetables,” (The FDA Guide). This publication informs the farmer about areas in production and handling that are in high risk of microbial contamination and how to minimized that exposure.

Soon after that publication was released, wholesale buyers of fresh fruits and vegetables started requiring their suppliers to undergo 3rd party audits to insure that Good Agricultural Practices (GAP) and Good Handling Practices (GHP) were being observed. That audit program insures that the standards outlined in the FDA Guide are being met.

GAP & GHP are voluntary programs. The Maryland Department of Agriculture, Food Quality Assurance Program has developed a state GAP/GHP certification program. This program is a good way to start developing better food safety practices on your farm if you have never had a GAP/GHP audit or inspection. The program includes development of a food safety plan, implementation of that plan, and an onsite inspection. Producers that pass receive a certificate. All levels of GAP/GHP look at various areas of practice. They include:

-

Developing a food safety plan

-

Water quality

-

Manure and municipal biosolids

-

Worker health and hygiene

-

Sanitary facilities

-

Field sanitation

-

Packing facility sanitation

-

Transportation

-

Trace back

Most Growers find that attending a Basic GAP training to be of great assistance in developing a food safety plan for their farm. Whether you are a farmer-in-training, beginning farmer, or have farmed for decades having a plan in place sets standards and practices for food safety in a progressive and organized fashion. Cornell College of Agriculture and Life Science has put together a good set of references here. A set of Produce Safety Rule and GAP compliant record templates are here.

Information on the MDA GAP program are found here:

MDA GAP Program Basic requirements

Top 10 Things to Implement – GAP Checklist

MDA GAP/GHP Inspection Request Form – word format

How Does The FSMA, Produce Safety Rule Affect Me?

I’m a PYO Fruit Grower….

I’m a Vegetable Farmer with a CSA………

I’m a Mostly Wholesale Grower with a Farm Stand….

I Raise Beef Cattle and Grow Vegetables for Our Family….

Does the Produce Safety Rule Affect Me?

The Produce Safety Rule (PSR) section of the U.S. Food Safety Modernization Act (FSMA) is aimed at reducing the risk of human exposure to microbial pathogens when fresh fruits and vegetables are consumed raw. Most all fruits and vegetables that are generally eaten raw are covered. *

The Produce Safety Rule is a mandatory federal regulation that is implemented based on the amount of produce sold and to whom.

You are exempt if you sold less than an average of $28,075 in covered and non-covered produce over the previous three-year period.

You are required to comply to the rule if you sold over an average of $561,494 in produce sales per year in the last three-year period.

It is the middle area – the qualified exempt status that gets complicated. A qualified exempt producer will meet the following criteria:

-

your average total food* sales were less than $561,494.

-

A lot will depend on what percentage of your food* sales were to “qualified end users”. So who is a qualified end user?

-

1. Your PYO and farm market customers

-

2. Restaurants and retail food stores in the same state and less than 275 miles away, and they sell directly to the consumer.

-

-

More than half (50.1%) of the value of the total food* sold went to the aforementioned qualified end users.

*For this calculation, grains, animal feeds, poultry, livestock, etc. are included

If you find that you fall into either the qualified exempt or required compliance categories, what do you do? The first step would be to attend a Produce Safety Alliance (PSA) training on the PSR. That training will outline the compliance requirements. Though lengthy, the PSR requirements are fairly common-sense standards and procedures that you are probably already implementing on your farm and are very similar to GAPs (Good Agricultural Practices) certification requirements.

You will need at least one person on your farm who has taken the training. It is very important that the PSA trained person be in a position to update procedures and train workers in the PSR standards.

In Maryland we are privileged to have the Maryland Department of Agriculture overseeing PSR compliance. Inspections of the larger producers have already started, and many farms are electing to have an On Farm Readiness Review (OFRR) before an inspection. The OFRR brings three specialists to your farm: someone from MDA, someone from your local extension office, and a food safety educator from the University of Maryland. This team will go over the compliance requirements with you and look specifically at your farm’s unique situation. Even the FDA is looking at these first years as a time of education not retribution. We in the Food Safety Group have attended many OFRR’s, and the farmer feedback is that they are very helpful and give real, reasonable application to what can be a confusing set of laws. The goal is to develop a food safety culture on your farm and with your workers to help keep your customers safe.

*The following are produce commodities that FDA has identified as rarely consumed raw: asparagus; black beans, great Northern beans, kidney beans, lima beans, navy beans, and pinto beans; garden beets (roots and tops) and sugar beets; cashews; sour cherries; chickpeas; cocoa beans; coffee beans; collards; sweet corn; cranberries; dates; dill (seeds and weed); eggplants; figs; ginger; horseradish; hazelnuts; lentils; okra; peanuts; pecans; peppermint; potatoes; pumpkins; winter squash; sweet potatoes; and water chestnuts

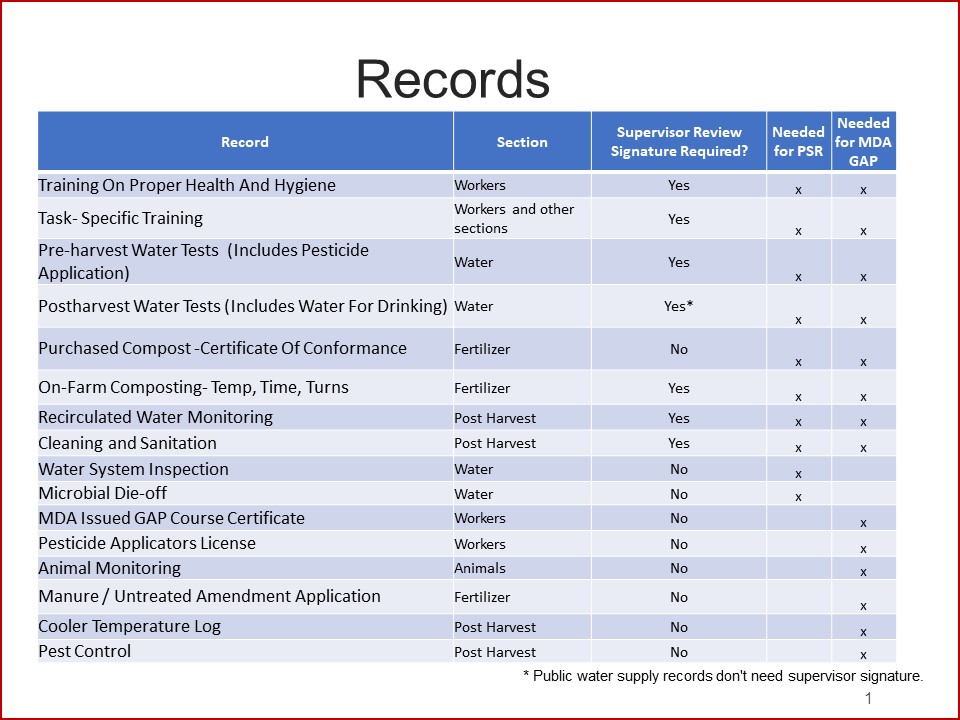

Record Keeping Templates

Keeping records is a requirement of both GAPs and the Produce Safety Rule. There are templates for many kinds of records found here